Rubber Bellow Seal

SEAL INFORMATION

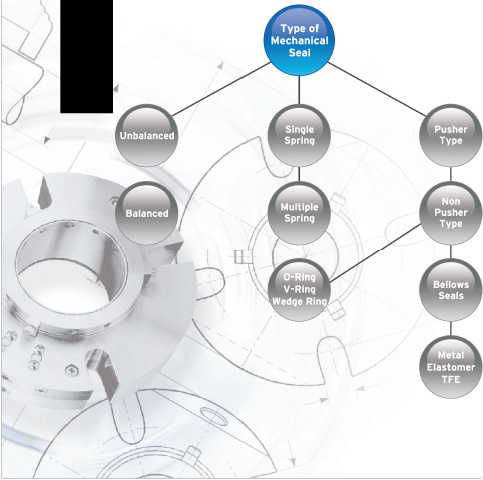

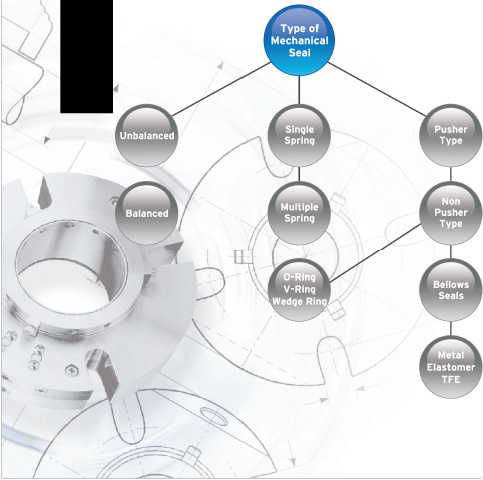

Mechanical seal basics

Mechanical seals are simply another means of controlling leakage of a process where other means are deemed to be less capable of performing the task adequately. Before the advent of mechanical seals, pump users relied primarily on "rope" or braided style packing to achieve a "seal" around the shaft. A series of pieces or "rings" were installed into the pump "stuffing box" and they were compressed tightly so that they created a difficult leak path for the liquid to negotiate in order to leak to atmosphere.

Mechanical seal is a device which is used to avoid leakage at pump, agitator etc. mechanical seals constituted by two sliding faces maintain by an axial forces. Their primary sealing is done by primary sealing ring and it's mating ring. In a properly designed seal they slide relative to each other.

The mechanical seal constitutes:

- Primary sealing ring and mating ring.

- Secondary seals consisting of o-ring or other suitable gasket.

- Hardware consisting mainly of spring and retainer.

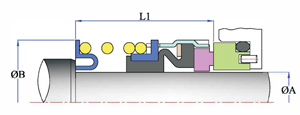

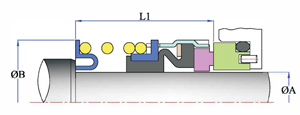

Type: CS 1

Features:

- Single seal

- Unbalanced

- Independent of direction of rotation

- Elastomer bellows

These seals has been designed for high volume production and reliable service using field-proven. The low-profile offers a unit with a very high degree of interchangeability.

Application:

Its used for medium pressure applications. For Centrifugal, Rotary & Turbine Pumps, Compressors, Mixers, Blenders, Chillers, Other Rotary Shaft Equipment.

Operating Condition :

- Temperature : -40°C to +140°C

- Pressure : up to 12 bar g

- Speed : up to 13 m/s

| Seal size (Inches) |

>ØA |

>ØB |

>L1 |

| 0.375 |

9.52 |

22 |

44 |

| 0.5 |

12.7 |

25 |

44 |

| 0.625 |

15.87 |

29 |

44 |

| 0.75 |

19.05 |

32 |

44 |

| 0.813 |

20.63 |

33 |

44 |

| 0.875 |

22.22 |

35 |

44 |

| 1 |

25.4 |

38 |

44 |

| 1.125 |

28.57 |

46 |

60 |

| 1.25 |

31.75 |

49 |

60 |

| 1.375 |

34.94 |

52 |

60 |

| 1.5 |

38.1 |

56 |

60 |

| 1.625 |

41.27 |

59 |

60 |

| 1.75 |

44.45 |

62 |

71 |

| 1.875 |

47.62 |

65 |

71 |

| 2 |

50.8 |

68 |

71 |

| 2.125 |

53.97 |

71 |

71 |

| 2.25 |

57.15 |

75 |

71 |

| 2.375 |

60.32 |

78 |

71 |

| 2.5 |

63.5 |

81 |

71 |

| 2.625 |

66.67 |

86 |

70 |

| 2.75 |

69.85 |

89 |

70 |

| 2.875 |

73.02 |

92 |

73 |

| 3 |

76.2 |

95 |

73 |

| 3.125 |

79.37 |

102 |

79 |

| 3.25 |

82.55 |

105 |

79 |

| 3.375 |

85.72 |

108 |

79 |

| 3.5 |

88.9 |

111 |

79 |

| 3.625 |

92.07 |

114 |

83 |

| 3.75 |

95.25 |

117 |

83 |

| 3.875 |

98.42 |

121 |

86 |

| 4 |

101.6 |

124 |

86 |

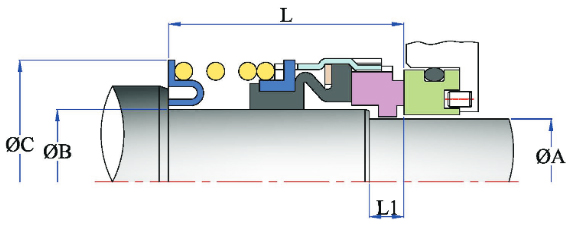

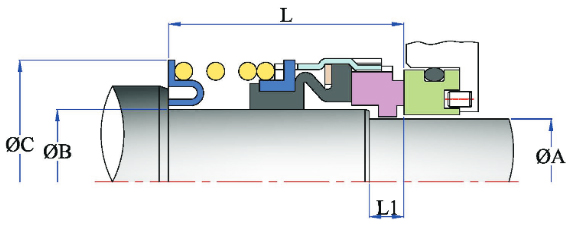

Type: CS 1B

Features:

- Single seal

- Balanced

- Independent of direction of rotation

- Elastomer bellows

CS 1B is suitable for wide range of service conditions from water & steam to chemicals corrosive materials. These seals has been designed for high volume production and reliable service using field-proven. The low-profile offers a unit with a very high degree of interchangeability.

Application:

Its used for medium pressure applications. For Centrifugal, Rotary & Turbine Pumps, Compressors, Mixers, Blenders, Chillers, Other Rotary Shaft Equipment.

For pulp and paper, petrochemical, food processing, wastewater treatment, chemical processing, power generation and other demanding applications

Operating Condition :

- Temperature : -40°C to +140°C

- Pressure : up to 40 bar g

- Speed : up to 13 m/s

| Seal size (Inches) |

>ØA |

>ØB |

>ØC |

>L |

>L1 |

| 1.25 |

28.6 |

31.75 |

49.2 |

60.3 |

7.9 |

| 1.375 |

31.7 |

34.92 |

52.4 |

60.3 |

7.9 |

| 1.5 |

34.9 |

38.1 |

55.6 |

60.3 |

7.9 |

| 1.625 |

38.1 |

41.27 |

58.7 |

60.3 |

7.9 |

| 1.75 |

41.3 |

44.45 |

61.9 |

70.6 |

7.9 |

| 1.875 |

44.4 |

47.62 |

65.1 |

70.6 |

7.9 |

| 2 |

47.6 |

50.79 |

68.3 |

70.6 |

7.9 |

| 2.125 |

50.8 |

53.97 |

71.4 |

70.6 |

7.9 |

| 2.25 |

54 |

57.15 |

74.6 |

70.6 |

7.9 |

| 2.375 |

57.1 |

60.32 |

77.8 |

70.6 |

7.9 |

| 2.5 |

60.3 |

63.5 |

81 |

70.6 |

7.9 |

| 2.625 |

63.5 |

66.67 |

85.7 |

79.4 |

17.5 |

| 2.75 |

66.7 |

69.85 |

88.9 |

79.4 |

17.5 |

| 2.875 |

69.8 |

73.02 |

92.1 |

82.5 |

17.5 |

| 3 |

73 |

76.19 |

95.2 |

82.5 |

17.5 |

| 3.125 |

73 |

79.37 |

101.6 |

88.9 |

22.5 |

| 3.25 |

76.2 |

82.55 |

104.8 |

88.9 |

22.5 |

| 3.375 |

79.4 |

85.72 |

107.9 |

88.9 |

22.5 |

| 3.5 |

82.5 |

88.9 |

111.1 |

88.9 |

22.5 |

| 3.625 |

85.7 |

92.07 |

114.3 |

92.1 |

22.5 |

| 3.75 |

88.9 |

95.25 |

117.5 |

92.1 |

22.5 |

| 3.875 |

92.1 |

98.42 |

120.6 |

95.2 |

22.5 |

| 4 |

95.2 |

101.62 |

123 |

95.2 |

22.5 |

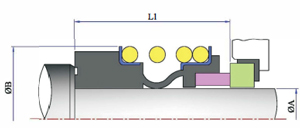

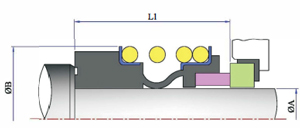

Type: CS 12

Features:

- Single Seal

- Unbalanced

- Independent of rotation of direction

- Elastomer Bellows

This mechanical seal is most commonly used. The bellow is not subjected to any torsional stress and its ingenious design incorporates several functions, as seal face carrier secondary sealing element and drive collar. The seal face is driven through the spring and L-rings.

Application :

It is used for Water and waste water technology, submersible pump, sewage pump and chemical industry etc.

Advantages

- Optimal alignment characteristic through self-cleaning of disk/shaft

- Improved centering across entire pressure operating range

- No torsion on bellows

- Shaft protection over entire seal length

- Protection of seal face during installation due to special bellows design

- Insensitive to shaft deflections due to large axial movement ability

- Suitable for low-end sterile applications

Operating Conditions :

- Temperature : -20°C to +120°C

- Pressure : 12 bar

- Speed : 20 m/s

| Seal size (Inches) |

ØA |

ØB |

L1 |

| 10 |

10 |

22.5 |

25.9 |

| 12 |

12 |

25 |

25.9 |

| 14 |

14 |

28.5 |

28.4 |

| 15 |

15 |

28.5 |

28.4 |

| 16 |

16 |

28.5 |

28.4 |

| 18 |

18 |

28.5 |

30 |

| 19 |

19 |

32 |

30 |

| 20 |

20 |

37 |

30 |

| 22 |

22 |

37 |

30 |

| 24 |

24 |

37 |

32.5 |

| 25 |

25 |

42.5 |

32.5 |

| 28 |

28 |

42.5 |

35 |

| 30 |

30 |

49 |

35 |

| 32 |

32 |

53.5 |

35 |

| 33 |

33 |

53.5 |

35 |

| 35 |

35 |

57 |

35 |

| 38 |

38 |

59 |

36 |

| 40 |

40 |

62 |

36 |

| 42 |

42 |

63.5 |

36 |

| 43 |

43 |

63.5 |

36 |

| 45 |

45 |

68 |

36 |

| 48 |

48 |

70.5 |

36 |

| 50 |

50 |

74 |

36 |

| 53 |

53 |

78.5 |

36.5 |

| 55 |

55 |

81 |

36.5 |

| 58 |

58 |

85.5 |

41.5 |

| 60 |

60 |

88.5 |

41.5 |

| 65 |

65 |

93.5 |

41.5 |

| 68 |

68 |

96.5 |

41.2 |

| 70 |

70 |

99.5 |

48 |

| 75 |

75 |

107 |

48 |

| 80 |

80 |

112 |

48 |

| 85 |

85 |

120 |

48 |

| 90 |

90 |

127 |

51 |

| 95 |

95 |

132 |

51 |

| 100 |

100 |

137 |

51 |

Type: CS 21

Features:

- Single seal

- unbalanced

- Single coil spring design

- Independent of direction of rotation

- Elastomer bellow

Application:

Water pumps, Submersible pump

Operating Condition:

- Temperature : -40°C to +140°C

- Pressure : up to 10 bar

- Speed : 20 m/s

| Seal size (Inches) |

A |

B |

L1 |

| 0.5 |

12.7 |

23.81 |

20.64 |

| 0.625 |

15.88 |

26.99 |

22.23 |

| 0.75 |

19.05 |

30.16 |

22.23 |

| 0.875 |

22.23 |

33.34 |

23.81 |

| 1 |

25.4 |

42.85 |

25.4 |

| 1.125 |

28.58 |

46.02 |

26.97 |

| 1.25 |

31.75 |

49.2 |

26.97 |

| 1.375 |

34.93 |

52.37 |

28.58 |

| 1.5 |

38.1 |

55.55 |

28.58 |

| 1.625 |

41.28 |

63.5 |

34.93 |

| 1.75 |

44.45 |

66.68 |

34.93 |

| 1.875 |

47.63 |

69.85 |

38.1 |

| 2 |

50.8 |

73.03 |

38.1 |

| 2.125 |

53.98 |

76.2 |

42.85 |

| 2.25 |

57.15 |

79.38 |

42.85 |

| 2.375 |

60.33 |

82.55 |

46.02 |

| 2.5 |

63.5 |

84.91 |

46.02 |

| 2.625 |

66.68 |

88.9 |

49.2 |

| 2.75 |

69.85 |

95.25 |

49.2 |

| 2.875 |

73.03 |

98.43 |

52.37 |

| 3 |

76.2 |

101.6 |

52.37 |

| 3.125 |

79.38 |

104.78 |

55.55 |

| 3.25 |

82.55 |

107.95 |

55.55 |

| 3.375 |

85.73 |

114.3 |

55.55 |

| 3.5 |

88.9 |

117.48 |

55.55 |

| 3.625 |

92.08 |

120.65 |

58.72 |

| 3.75 |

95.25 |

123.83 |

58.72 |

| 3.875 |

98.43 |

127 |

61.9 |

| 4 |

101.6 |

130.18 |

61.9 |