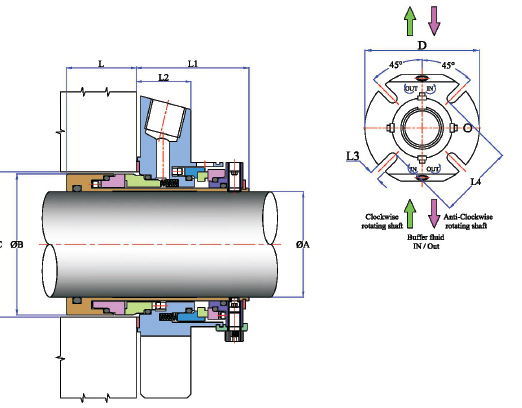

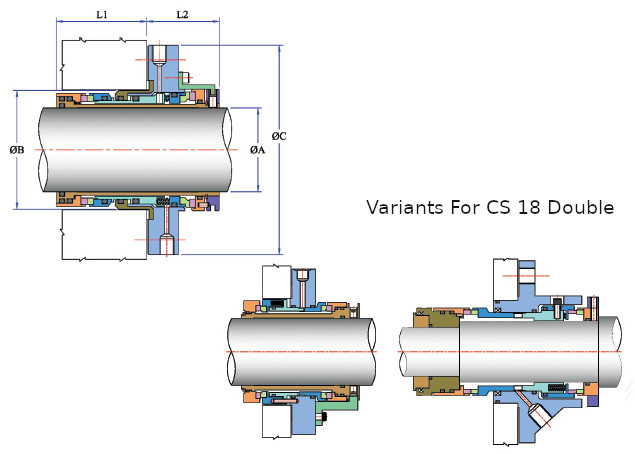

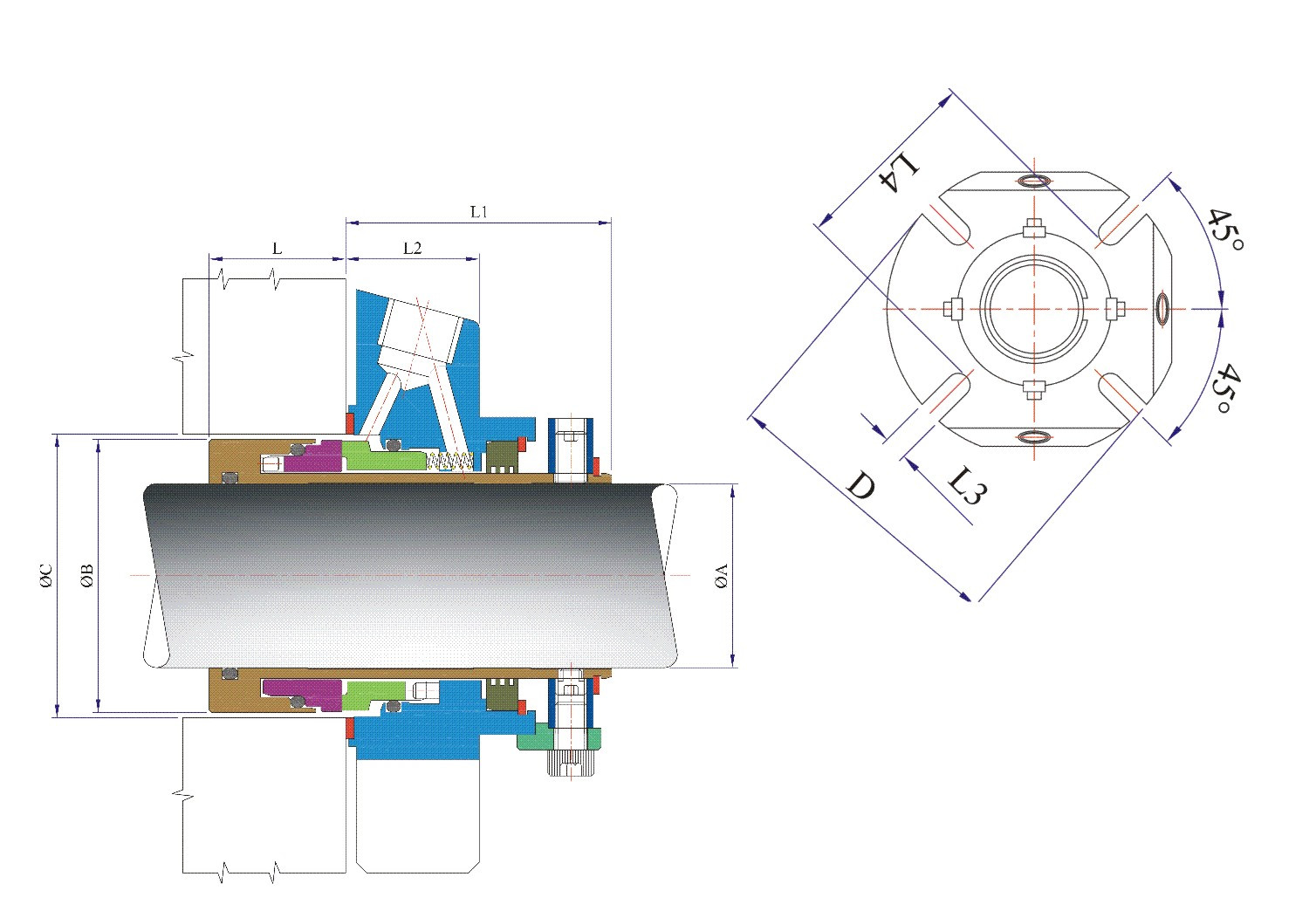

Type: CS 22

| Seal size | ØA | ØB | ØC MIN | ØC MAX | L | L1 | L2 | L3 | L4 | D |

| 25 | 25 | 42 | 44 | 51.5 | 26 | 50.6 | 25.5 | 13.5 | 62 | 105 |

| 28 | 28 | 45 | 47 | 52 | 26 | 50.6 | 25.5 | 13.5 | 62 | 105 |

| 30 | 30 | 47 | 49 | 56 | 26 | 50.6 | 25.5 | 13.5 | 65 | 105 |

| 32 | 32 | 48.8 | 51 | 57 | 26 | 50.6 | 25.5 | 13.5 | 67 | 110 |

| 33 | 33 | 48.8 | 51 | 57 | 26 | 50.6 | 25.5 | 13.5 | 67 | 110 |

| 35 | 35 | 52 | 54 | 61.5 | 26 | 50.6 | 25.5 | 13.5 | 70 | 113 |

| 38 | 38 | 55 | 57 | 66 | 26 | 50.6 | 25.5 | 13.5 | 75 | 123 |

| 40 | 40 | 57 | 59 | 68 | 26 | 50.6 | 25.5 | 14.5 | 75 | 123 |

| 42 | 42 | 59.5 | 61.5 | 69 | 26 | 50.6 | 25.5 | 14.5 | 80 | 133 |

| 43 | 43 | 59.5 | 61.5 | 70.5 | 26 | 50.6 | 25.5 | 14.5 | 80 | 133 |

| 45 | 45 | 61.5 | 64 | 73 | 26 | 50.6 | 25.5 | 14.5 | 81 | 138 |

| 48 | 48 | 64.5 | 67 | 75 | 26 | 50.6 | 25.5 | 14.5 | 84 | 138 |

| 50 | 50 | 67 | 69 | 78 | 26 | 50.6 | 25.5 | 14.5 | 87 | 145 |

| 53 | 53 | 71 | 73 | 83 | 26 | 50.6 | 25.5 | 18 | 97 | 145 |

| 55 | 55 | 72 | 74 | 87 | 26 | 50.6 | 25.5 | 18 | 90 | 145 |

| 60 | 60 | 77 | 79 | 91 | 26 | 50.6 | 25.5 | 18 | 102 | 155 |

| 65 | 65 | 83.8 | 85.7 | 98.5 | 26 | 50.6 | 25.5 | 18 | 109 | 163 |

| 70 | 70 | 92 | 95 | 108 | 26 | 50.6 | 25.5 | 18 | 118 | 175 |

| 75 | 75 | 99 | 101.6 | 118 | 34 | 57.5 | 28 | 18 | 129 | 178 |

| 80 | 80 | 105.5 | 108 | 124 | 34 | 57.5 | 28 | 18 | 135 | 195 |

| 85 | 85 | 108.5 | 111.1 | 128 | 34 | 57.5 | 28 | 22 | 139 | 198 |

| 90 | 90 | 115 | 117.5 | 135 | 34 | 57.5 | 28 | 22 | 145 | 205 |

| 95 | 95 | 118 | 120.7 | 138 | 34 | 57.5 | 28 | 22 | 148 | 208 |

| 100 | 100 | 124.5 | 127 | 144 | 34 | 57.5 | 28 | 22 | 154 | 218 |

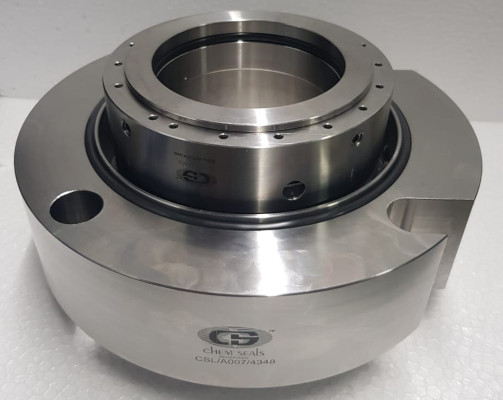

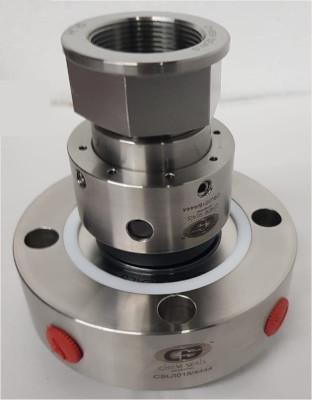

Features:

- Single seal

- Balanced

- Independent of direction of rotation

- Cartridge unit

- Easy installation

Application:

This seal is used for handling slurries, sludges, syrups. The springs are isolated from media being sealed by dynamic elastomer.

Operating Condition:

- Temperature : -20 ° C to +220 °C

- Pressure : Upto 25 bar

- Speed : 20 m/s