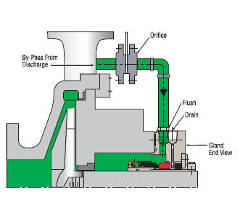

Api Plan 11

Description

Product recirculation from pump discharge to seal through a flow control orifice.

Features

- Prevents product from vaporizing by maintaining positive pressure above vapour pressure

- Becomes a self-venting plan for horizontal pumps

- Default API Plan for most single seals.

Use

- In general, applications with clean non-polymerizing fluids with moderate temperatures.

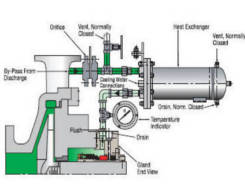

Api Plan 21

Description

Product recirculation from discharge through flow control orifice and heat exchanger to seal chamber.

Features

- Improves pressure margin over vapour pressure

- Improves temperature margin to meet secondary sealing element limits, to reduce coking or polymerizing and to improve lubricity

- Self venting plan

- Provides sufficient pressure difference to allow proper flow rate.

Use

- For high temperature applications e.g. hot water application(temperature>80°C)hot hydrocarbons etc.

- In hot non-polymerizing fluids.

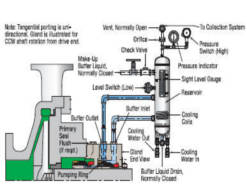

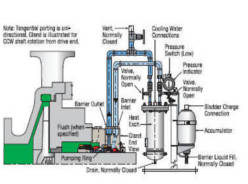

Api Plan 52

Description

Depressurised buffer fluid circulation in outboard seal of a dual seal configuration through a seal support system.

Circulation is maintained by using pumping ring in running condition and by thermosyphon effect in stand still condition.

Features

- No process contamination.

- No direct process leakage to atmosphere

- No need to maintain pressure system as in Plan 53A

Use

- For media where product dilution is not allowed but leakage to atmosphere in diluted form may be allowed

- Preferred for clean, non-polymerizing media with vapour pressure higher than buffer fluid pressure (ls also used for lower vapour pressure media).

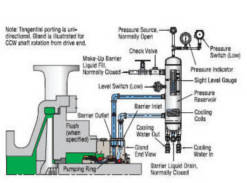

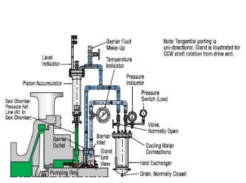

Api Plan 53A

Description

Pressurised barrier fluid circulation in outboard seal of dual seal configuration through a seal support system. Circulation is maintained by using pumping ring in running condition and with thermosyphon effect in stand still condition.

Features

- In no case will media leak to atmosphere (Provided the seal support system pressure is not lost).

- Clean fluid film formation between the inboard seal faces gives better seal life.

- Works as a Plan 52 arrangement if barrier fluid pressure is lost.

Use

- Applications where no leakage to atmosphere can be tolerated e.g. hazardous, toxic, inflammable media.

- For dirty, abrasive or polymerizing products where media is unsuitable as a lubricant for inboard seal faces.

Api Plan 53B

Description

Pressurised barrier fluid circulation in outboard seal of dual seal configuration. Circulation is maintained by using pumping ring in running condition and with thermosyphon effect in stand still condition. The pressure is maintained in the seal circuit by a bladder accumulator

Features

- Keeps barrier fluid and pressurised gas (inert gas) separate by using a bladder.

- Heat is removed from the circulation system by an air-cooled or water-cooled heat exchanger.

- Being a stand-alone system does not rely upon a central pressure source. Hence much more reliable than a Plan 53k

- In no case will media leak to atmosphere

- Clean fluid film formation between the inboard seal faces gives better seal life

Use

- Applications where no leakage to atmosphere can be Tolerated e.g. hazardous, toxic• inflammable media

- For dirty, abrasive or polymerizing products where media is unsuitable as a lubricant for inboard seal faces.

Api Plan 53C

Description

Pressurised barrier fluid circulation in outboard seal of dual seal configuration. Circulation is maintained by using pumping ring in running condition and with thermosyphon effect in stand still condition.

The pressure is maintained and fluctuations are compensated in the seal circuit by a piston type accumulator.

Features

- Vent system properly before start up

- Heat is removed from the circulation system by an air-cooled or water-cooled heat exchanger.

- Heat is removed from the circulation system by an air-cooled or water-cooled heat exchanger.

- In no case will media leak to atmosphere

- Clean fluid film formation between the inboard seal faces gives better seal life.

- This allows successful operation of dual seals lacking reverse balance feature at inboard seal, when having highly variable seal chamber pressure.

Use

- Applications where no leakage to atmosphere can be tolerated e.g. hazardous, toxic, inflammable media.

- For dirty, abrasive or polymerizing products where media is unsuitable as a lubricant for inboard seal faces

- Where pump pressure varies during operation needing an auto setting of barrier fluid pressure, thus maintaining the same differential throughout.

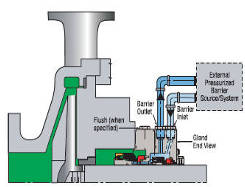

Api Plan 54

Description

Pressurised external barrier fluid circulation from a central pressure source or by a stand alone pumping unit.

Features

- Vent system properly before start up

- Ensures higher flow rate, better heat dissipation and positive circulation of barrier fluid.

- If maintained properly, is the most reliable pressurised plan for dual seals as compared to Plan 53 A/B/C

- Can also be given as a stand alone unit per pump

- Increases cooler efficiency due to higher flow rate the heat exchanger

Use

- Applications where no leakage to atmosphere can be tolerated e.g. hazardous, toxic, inflammable

- For dirty, abrasives or polymerizing products where media is unsuitable as a lubricant for inboard seal faces.

- For media with high pressure and / or high temperature and / or high heat generation between faces

- Wherever Plan 53 A/B/C circulation is insufficient to dissipate heat.

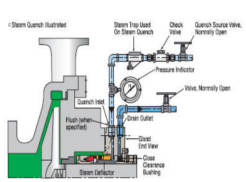

Api Plan 62

Description

An external fluid stream is brought to atmospheric side of the seal faces using quench and drain connections.

Features

- The quench fluid acts as barrier in between atmosphere and process fluid

- The quench fluid reduces oxidation and coking of product and also cools seal faces

- Flushes away undesirable material build up under seal faces.

- Can be used with water, steam or an inert gas.

Use

- In caustic or crystallising fluids.

- In oxidizing fluids or hot hydrocarbons.

- Can be used to purge steam in hot applications especially for stationary bellows to avoid coking