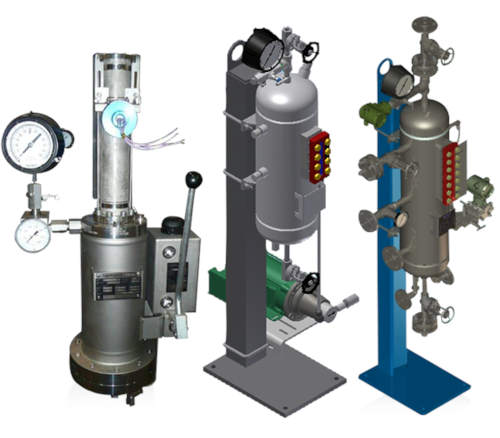

A seal support system allows pressurised barrier fluid circulation in the outboard seal of a dual seal design. Circulation is maintained by using a pumping ring when running and a thermosyphon effect when not running.

Anti-friction properties, Chemical resistance, Temperature resistance, Compressibility and resilience, Retention of lubricants, non-corrosive, wear-resistant.

1. No media will leak into the atmosphere (Provided the seal support system pressure is not lost).

2. A clean fluid film between the inboard seal faces increases seal life.

3. If the barrier fluid pressure is lost, it acts as a Plan 52 configuration.

1. Applications where no leakage to the atmosphere is acceptable, such as dangerous, poisonous, or combustible media.

2. For unclean, abrasive, or polymerizing materials when media is unsuitable as an inboard seal face lubricant.

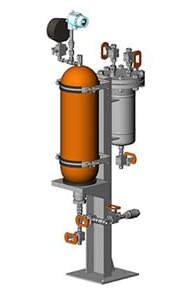

Pressurized barrier fluid circulation in the outboard seal of a dual seal system. Circulation is maintained by using a pumping ring when running and a thermosyphon effect when not running. A bladder accumulator keeps the pressure in the seal circuit constant.

1. A bladder separates barrier fluid and pressurised gas (inert gas).

2. An air-cooled or water-cooled heat exchanger removes heat from the circulation system.

3. Because it is a stand-alone system, it does not require a central pressure source. As a result, it is far more trustworthy than Plan 53A.

4. No media will ever leak into the atmosphere.

5. A clean fluid film formed between the inboard seal faces extends seal life.

1. Applications where no leakage to the atmosphere is acceptable, such as dangerous, poisonous, or combustible media.

2. For unclean, abrasive, or polymerizing materials when media is unsuitable as an inboard seal face lubricant.