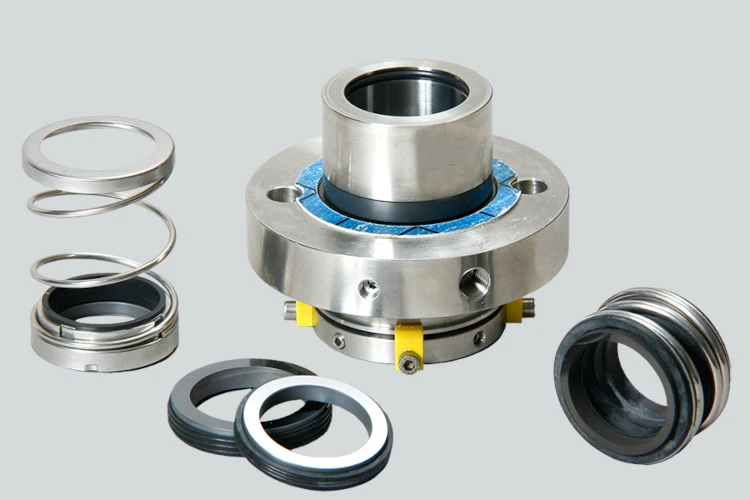

The selection of the correct seal face materials is critical to the mechanical seal's performance. It might be said that the seal designer's material selection is the most crucial decision he or she will make. Both the qualities of the individual materials and the combination of the tribological pair must be considered when considering materials for seal faces. Seal faces . . .